Yash Electronics

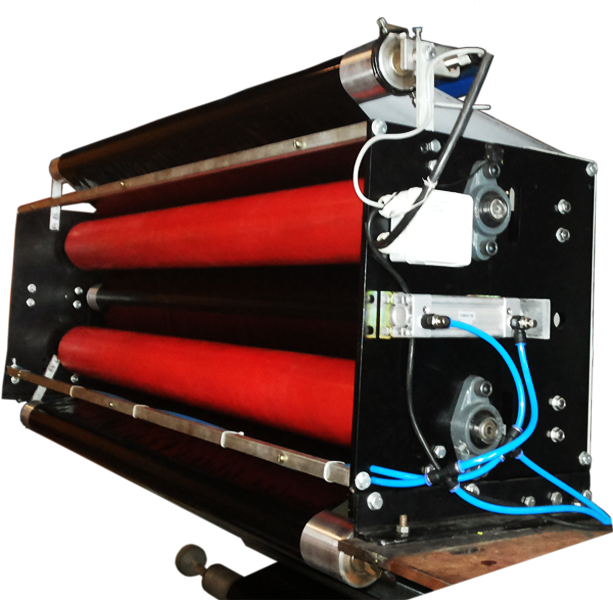

Yash Electronics are manufacturer's of Corona Treaters and Induction Cap Sealing machines.

Additionally We provide You with wide range products, sales and services in relation with Corona Treaters and Induction Cap Sealing machines.

Yash Electronics are manufacturer's of Corona Treaters and Induction Cap Sealing machines.

Additionally We provide You with wide range products, sales and services in relation with Corona Treaters and Induction Cap Sealing machines.

Customer Stories

Customer Stories

We installed High frequency Corona Treater which resulted in achieving 48 dynes at speed of 60 MPM.

Provides manufacturing in Corona Treaters & Induction Sealers, additionally we provide you with professional services in this field.

Our team carries an experience over 22 years, hence are capable to provide you with better cost effective solutions.

Mr. Sandesh Mhatre is founder and Director of Yash Electronics with vast experience in the feild of Electronics since 1992.